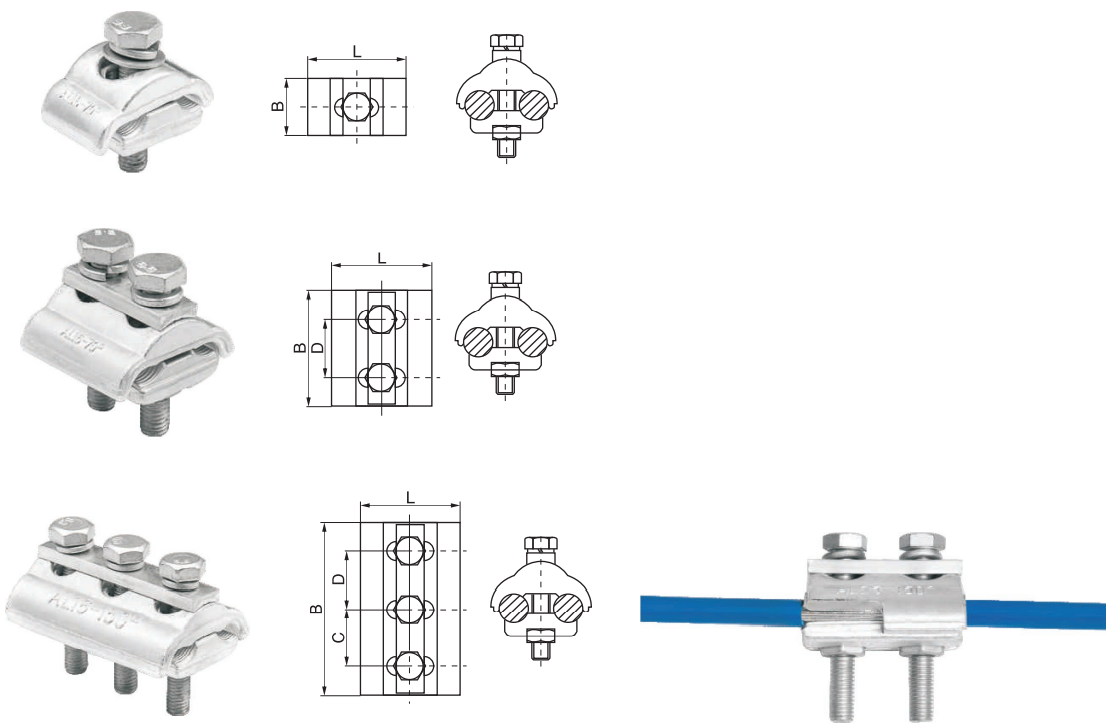

Aluminum Copper and Bimetallic type Connectors

Technical Data

| Model | Conductor Cross-section(mm2)

Cu 6-50 Al 16-70 |

Bolts |

| CAPG-A1 | Cu 10-95 Al 25-150 | 1×M8×40 |

| CAPG-A2 | Cu 6-50 Al 16-70 | 1×M8×45 |

| CAPG-B1 | Cu 10-95 Al 25-150 | 2×M8×45 |

| CAPG-B2 | Cu 25-185 Al 35-200 | 2×M8×50 |

| CAPG-B3 | Cu 6-50 Al 16-70 | 2×M10×60 |

| CAPG-C1 | Cu 10-95 Al 25-150 | 3×M8×45 |

| CAPG-C2 | Cu 25-185 Al 35-240 | 3×M8×50 |

| CAPG-C3 | Cu 35-240 Al 35-300 | 3×M10×60 |

| CAPG-C4 | 3×M10×70 |

Material

High strength aluminum alloy by forging. Surface treatment: Bright.

Product property

ALPG is used for connecting or branching AAC, AAAC or ACSR overhead conductors. Forging creates a high strength clamp. Slotted holes allow adjustment for varying conductors on each side. Its type test is in accordance with IEC61238-1.

Technical Data

|

Model |

Conductor Cross-section(mm2) | Bolts |

|

APG-A1 |

Al 16-70 | 1×M8×40 |

|

APG-A2 |

Al 16-150 | 1×M8×45 |

|

APG-B1 |

Al 16-35 | 2×M6×35 |

|

APG-B2 |

Al 16-70 | 2×M8×45 |

|

APG-B3 |

Al 16-150 | 2×M8×50 |

|

APG-B4 |

Al 25-185 | 2×M10×60 |

|

APG-C1 |

Al 16-70 | 3×M8×45 |

|

APG-C2 |

Al 16-150 | 3×M8×50 |

|

APG-C3 |

Al 25-240 | 3×M10×60 |

|

APG-C4 |

Al 35-300 | 3×M10×70 |

Parallel Groove Clamps Copper Extruded type

The clamp was designed to connect two parallel bare conductors. Conductors can be copper stranded or rods. Material is forged copper for copper to copper connection throughout the conductor range. The clamps have serrated transverse grooves for maximum conductor contact, use copper bolts and utilise Belleville washers to prevent thermal ratcheting under cyclic loads. The clamps are coated with an oxide inhibitor. And stainless botls and nuts with washers was on requirement.

For tap-off connections of copper-conductors acc. to DIN 48201

Material

Body: Copper alloy

Bolts: steel or stainless steel Nuts: DIN 934, steel Surface: uncoated

| Model | Bolt Torque | Conductor Range mm2 | Dimensions mm O.D | No./Size of Bolts |

| CU6-70-2 | 20Nm | 6 to 70 | 2.7 to 10.5 | 2×M8 |

| CU16-95-2 | 20Nm | 16 to 95 | 5.1 to 12.5 | 2×M8 |

| CU16-150-2 | 30Nm | 16 to 150 | 5.1 to 15.7 | 2×M10 |

| CU150-240-2 | 40Nm | 150 to 240 | 15.7 to 20.3 | 2×M12 |

| CU300-400-3 | 40Nm | 300 to 400 | 22.6 to 26.7 | 3×M12 |